VOCs处理 - 模组化设备

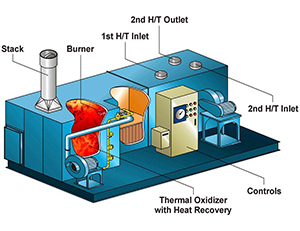

Thermal Oxidizer

Thermal Oxidizer (Recuperative) – T.O

RECUPERATIVE DESIGN FEATURES

Recuperative thermal oxidizers can be applied to almost all combustible organic pollutants in a vapor state. The oxidizers are applied in virtually any industry, but can oft en be found in chemical, pharmaceutical, printing, coating, paper, textile and paint finishing applications.

Recuperative oxidizer units are most economical when excess thermal energy can be recovered for use elsewhere in the production processes. Recuperative oxidizer operating costs are lower when the incoming solvent concentration is high, so less burner fuel is required.

MICRO-RECUP 8,000 SCFM, WOOD PRODUCTS INDUSTRY

RECUPERATIVE THERMAL OXIDIZER

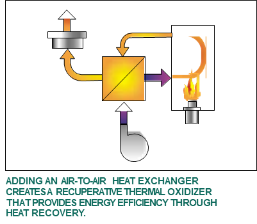

This type of oxidation technology uses a conventional type of heat exchanger to preheat the incoming air with air from the oxidation process.

- Integral primary heat recovery up to 83%

- Secondary heat recovery available

- Dedicated combustion air supply

- 99% VOC destruction efficiency

- Refactory lined combustion chamber

换热式氧化炉

- 整体一次热回收率高达 83%

- 可进行二次热回收

- 专用助燃空气供应

- 99% 的 VOC 破坏效率

- 耐火内衬的燃烧室

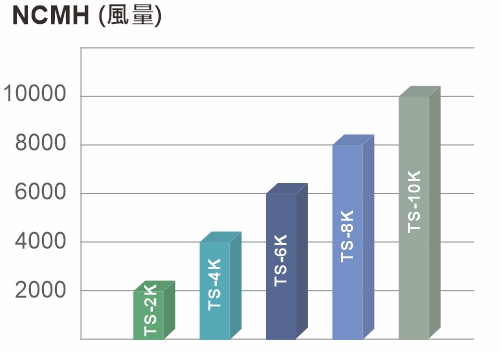

| TYPE | NCMH | L (mm) | W (mm) | H (mm) | Weight (KG) |

| TS-1000 | 1000 | ||||

| TS-2000 | 2000 | ||||

| TS-3000 | 3000 | ||||

| TS-4000 | 4000 | ||||

| TS-5000 | 5000 |